-

Insulation paper

Epoxy diamond dotted paper , kraft paper , cable paper ,crepe paper crepe paper tube ,pressboard , strips for making distribution transformer

Read More -

FRP PRODUCTS

dog bone , T bar , spacer ,R-angle , Round Bar Rectangular Bar ,Flat bar silicon part for dry transformer

Read More -

-

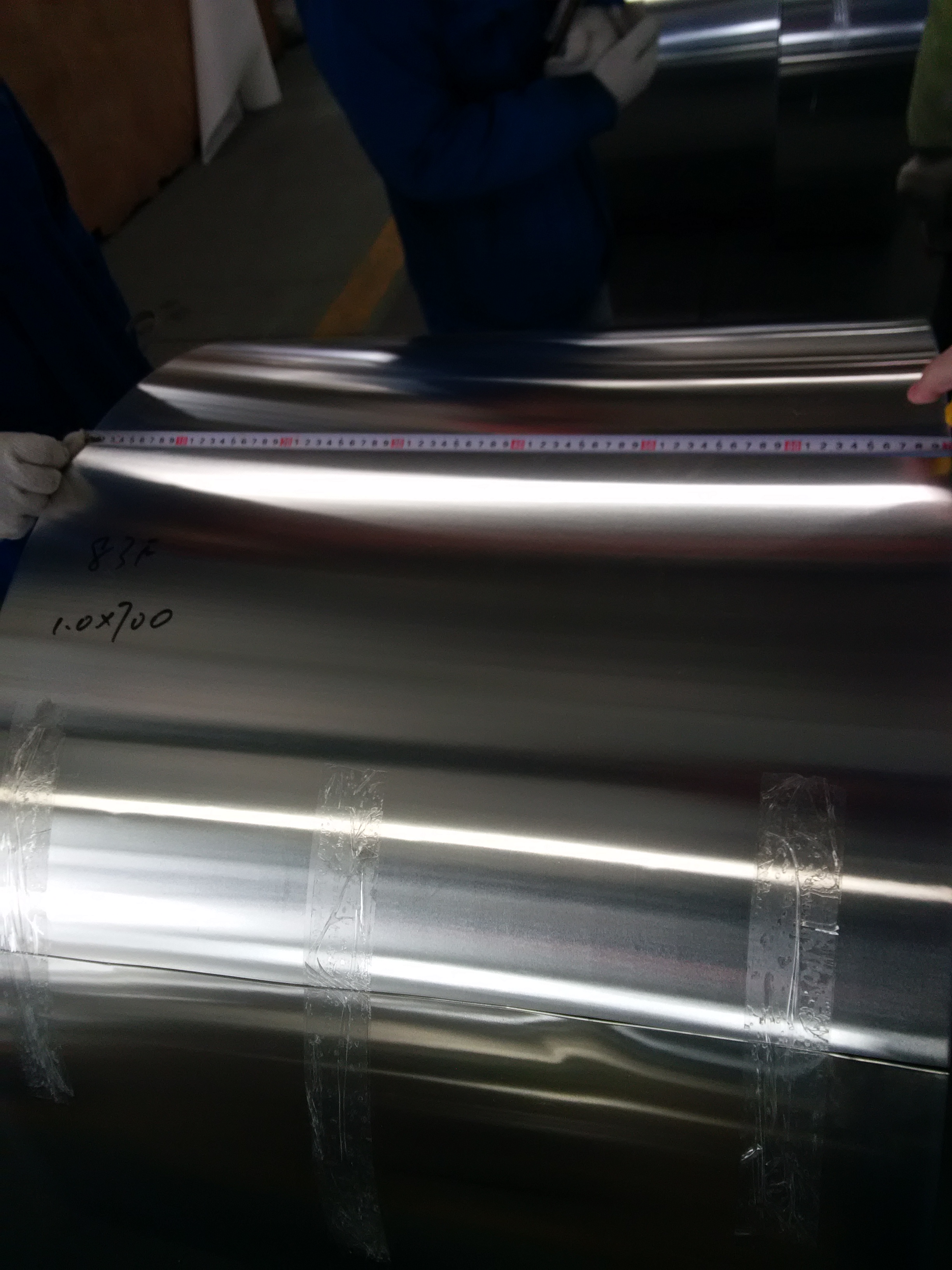

Lamination Sheet

Lamination sheet Inculding epoxy lamination sheet , phenlic paper laminated sheet . cotton phenlic lamiante sheet

Read More -